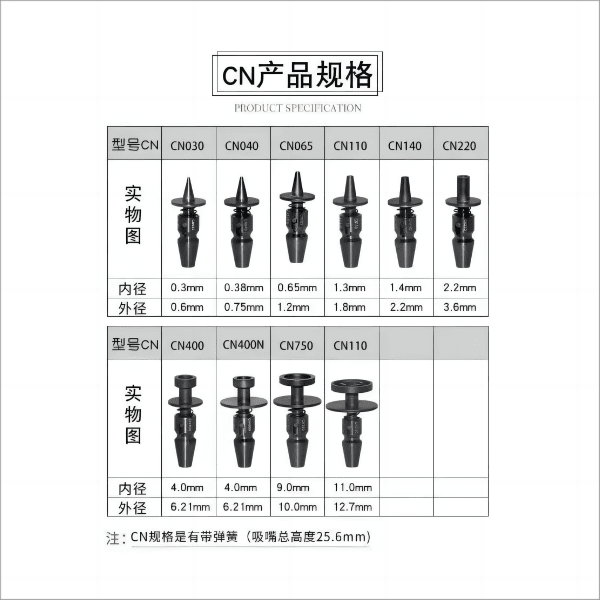

Hanwha SM482 Samsung Nozzle SMT SM451 Nozzle CP40

Crafted through a meticulous process, ceramic nozzles undergo transformation within a searing furnace, reaching temperatures of up to 2000 degrees. This metamorphosis grants them exceptional attributes: unparalleled wear resistance, the ability to endure extreme temperatures, and a remarkable hardness. These qualities synergistically amplify the longevity of consumable nozzle SMT, elevating their durability and ensuring sustained performance. The fusion of intricate craftsmanship and innovative material science results in ceramic nozzles that stand as guardians of longevity, fortifying the endurance of essential SMT components.